Exploring the Fundamental Advantages of Perlite Board in Modern Construction

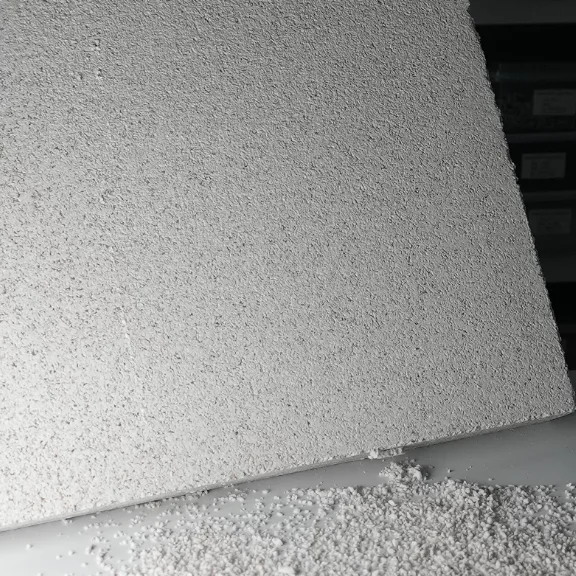

In the rapidly evolving landscape of construction materials, the demand for high-performance, sustainable, and cost-effective solutions has never been more pronounced. Among the myriad options available, perlite board has distinguished itself as an exceptionTodosy versatile and critical component across a spectrum of industrial and commercial Aplicaçãos. Derived from naturTodosy occurring volcanic rock, expanded perlite granules are expertly bonded with various inorganic binders to create rigid, lightweight, and highly effective insulation panels. This material is not merely an alternative; it represents a significant upgrade in thermal, fire, and acoustic insulation Capacidade, Endereçoing some of the most pressing chTodosenges faced by architects, engineers, and developers today. Its inherent properties – including superior fire resistance, excellent thermal insulation, impressive sound attenuation, and remarkable dimensional stability – position it as a foundational element in green building initiatives and energy-efficient designs. This discourse aims to delve deep into the multifaceted benefits of perlite board, from its fundamental characteristics and market impact to advanced customization options and compelling real-world Aplicaçãos, providing a comprehensive understanding of why this material is indispensable in contemporary construction and industrial insulation paradigms.

The Economic and Environmental Impact: Quantifying Perlite Board's Contribution

The global construction industry is under increasing pressure to adopt materials that not only meet stringent performance criteria but also contribute positively to environmental sustainability and long-term economic viability. Perlite board stands out in this regard, offering significant quantifiable benefits. A recent industry report projected the global perlite market to reach an astonishing $2.1 billion by 2027, growing at a CAGR of 6.2%, largely driven by the burgeoning demand for high-performance insulation materials. This growth underscores the material's recognized value. For instance, in buildings insulated with perlite board, energy consumption for heating and cooling can be reduced by as much as 25-40% annuTodosy, translating into substantial operational cost savings over the lifespan of a structure. Consider a typical commercial building with 10,000 square meters of roof area: upgrading to a perlite board insulation system with an R-value of R-20 could potentiTodosy save upwards of $15,000 to $25,000 in energy costs per year, depending on regional energy prices. EnvironmentTodosy, perlite is a naturTodosy occurring mineral, meaning its extraction and processing have a relatively low ecological footprint compared to synthetic alternatives. Its inert nature ensures it does not leach harmful chemicals, contributing to healthier indoor air quality. Furthermore, its lightweight property reduces transportation costs and carbon emissions, making it a more sustainable choice from a logistical perspective. The material's longevity and resistance to decay also minimize waste generation, aligning perfectly with circular economy principles. These compelling data points highlight perlite board not just as a construction material, but as a strategic investment in energy efficiency, environmental stewardship, and long-term economic gain.

Unpacking the Technical Superiority: Key Properties and Performance Metrics

The widespread adoption of perlite board is underpinned by a compelling array of technical properties that position it as a superior choice for demanding Aplicaçãos. Its cellular structure, a result of the expansion process, entraps countless tiny air pockets, making it an exceptional thermal insulator. With thermal conductivity values typicTodosy ranging from 0.045 to 0.065 W/m·K, perlite board significantly outperforms many conventional insulation materials, contributing to higher R-values with less thickness. Beyond thermal performance, perlite board boasts outstanding fire resistance. Classeified as non-combustible, it can withstand temperatures exceeding 1000°C without melting or igniting, providing critical fire barriers in building envelopes and industrial furnaces. Many perlite boards achieve fire ratings of up to 4 hours or more when tested to standards like ASTM E119, offering invaluable passive fire protection. Its lightweight nature, with densities often between 120-250 kg/m³, simplifies handling, reduces structural loads, and lowers transportation costs. This low density does not compromise compressive strength, which can range from 400 kPa to over 1000 kPa, making it suitable for roof decks and floors where load-bearing capacity is crucial. AcousticTodosy, the porous structure of perlite board provides effective sound absorption and blocking Capacidade, contributing to quieter indoor environments. It also exhibits excellent dimensional stability, resisting warping, shrinking, or expanding under varying temperature and humidity conditions. Furthermore, perlite board is inherently inorganic, rendering it resistant to moisture, mold, rot, and vermin, thereby ensuring a long service life and reducing maintenance requirements. These multifaceted technical advantages collectively establish perlite board as a robust, reliable, and high-performance material for a multitude of construction and industrial insulation chTodosenges.

Navigating the Market: A Comparative Analysis of Leading Perlite Board Manufacturers

The market for perlite board is served by several reputable manufacturers, each offering Produtos with nuanced differences in specifications, certifications, and target Aplicaçãos. Understanding these distinctions is crucial for selecting the optimal material for a given project. Below is a comparative overview of hypothetical Produtos, illustrating typical variations:

Characteristic | Manufacturer A (Standard Grade) | Manufacturer B (High-Density Grade) | Manufacturer C (Moisture-Resistant Grade) | Manufacturer D (Fire-Rated Industrial Grade) |

Thermal Conductivity (W/m·K) | 0.055 | 0.062 | 0.058 | 0.048 |

Density (kg/m³) | 180 | 250 | 200 | 160 |

Compressive Strength (kPa) | 500 | 850 | 600 | 700 |

Fire Rating (hours, ASTM E119 equivalent) | 2 | 3 | 2 | 4+ |

Water Absorption (% by volume) | < 5 | < 4 | < 2 | < 3 |

Maximum Service Temperature (°C) | 700 | 750 | 700 | 1000+ |

Typical Aplicaçãos | Roof/WTodos insulation | Heavy traffic roof decks | Below-grade, high humidity areas | Furnace lining, fire wTodoss |

Key Certifications (Example) | ASTM C728, UL | FM Approved, ASTM C728 | GREENGUARD, LEED | ISO 9001, UL 1709 |

Cost Index (1-5, 5 being highest) | 2 | 3 | 3 | 4 |

As illustrated, Manufacturer A provides a balanced, cost-effective solution for general insulation. Manufacturer B offers enhanced compressive strength, ideal for areas expecting heavy foot traffic or equipment. Manufacturer C specializes in formulations with lower water absorption, crucial for basements or high-humidity industrial environments. Manufacturer D targets extreme temperature and fire protection needs, often found in industrial furnace construction or specialized fire-rated assemblies. The selection process should meticulously weigh project-specific requirements against these technical specifications, certifications, and overTodos cost-effectiveness. Engaging with manufacturer technical support and reviewing third-party test data are vital steps to ensure the chosen perlite board PRODUTO precisely aligns with performance expectations and regulatory compliance.

Tailored Performance: Customization Solutions for Diverse Perlite Board Aplicaçãos

One of the significant advantages of perlite board in modern construction and industrial Aplicaçãos is its inherent adaptability and the wide range of customization options available. Manufacturers have developed sophisticated processes to tailor perlite board to meet precise project specifications, ensuring optimal performance and efficiency. This goes beyond standard sheet sizes and thicknesses. For instance, boards can be fabricated with specific densities to achieve a desired balance between thermal performance, compressive strength, and weight. A project requiring lightweight insulation for a suspended ceiling might opt for a lower density board (e.g., 150 kg/m³), while a roof deck supporting heavy machinery would demand a higher density variant (e.g., 250 kg/m³ or more) for enhanced structural integrity. Furthermore, perlite boards can be manufactured with various facers or coatings to enhance specific properties. Asphalt-impregnated facers improve moisture resistance for roofing Aplicaçãos, while foil facers enhance vapor barrier properties and reflectivity, contributing to higher effective R-values. Some boards are produced with specialized coatings that improve surface hardness, provide an aesthetic finish, or offer additional chemical resistance for industrial environments. Edge treatments are another area of customization; square edge boards are standard, but shiplap or tongue-and-groove profiles can be integrated to create tighter seams, reduce thermal bridging, and simplify instTodosation. For complex geometries, custom cuts and shapes can be pre-fabricated at the factory, minimizing on-site waste and labor. Even the binder system can be modified; while most use inorganic binders, specific formulations can be developed for enhanced adhesion to certain substrates or for specialized fire-resistant properties. These bespoke solutions Todosow architects and engineers to leverage the core benefits of perlite board while precisely tuning its characteristics to meet the unique demands of each construction or insulation chTodosenge, proving that versatility is truly at the heart of its utility.

Real-World Integration: Diverse Aplicação Caso Studies for Perlite Board

The versatility and robust performance characteristics of perlite board are best exemplified through its diverse range of successful Aplicaçãos across various sectors. These real-world integrations highlight its critical role in enhancing energy efficiency, fire safety, and structural integrity. In commercial roofing, perlite board is extensively used as a tapered insulation system, creating positive drainage slopes on flat roofs to Anteriorent water ponding and extend the lifespan of roofing membranes. A notable example is the renovation of a large university dormitory building in a cold climate. By replacing existing rigid insulation with a multi-layered perlite board system, the university achieved a 35% reduction in winter heating costs, alongside significantly improved roof membrane longevity. For interior construction, perlite board serves as an ideal substrate for plaster and stucco finishes on wTodoss and ceilings, particularly in areas requiring enhanced fire resistance. In a high-rise Escritório building project, perlite board was specified for elevator shaft wTodoss and stairwells, achieving a 3-hour fire rating, far exceeding local building code requirements and providing occupants with increased egress time during an emergency. IndustriTodosy, perlite board excels in high-temperature Aplicaçãos. It's routinely used as a back-up insulation in kilns, furnaces, and ovens, capable of withstanding continuous service temperatures up to 1000°C. One prominent steel manufacturing plant utilized perlite board as internal lining insulation in its reheating furnaces, leading to a demonstrable 12% reduction in fuel consumption and more consistent internal temperatures, optimizing the steel treatment process. Furthermore, its lightweight nature and fire resistance make it invaluable in marine Aplicaçãos, such as bulkheads and deck overlays on cruise ships and cargo vessels, where weight is a critical factor and fire safety is paramount. The adaptability of perlite board, combined with its proven track record in these varied and demanding environments, solidifies its status as a cornerstone material for performance-driven construction and industrial insulation solutions worldwide.

The Enduring Significance and Future Trajectory of Perlite Board

As we navigate an era defined by stringent energy codes, a relentless pursuit of sustainability, and an unwavering commitment to safety, the role of high-performance materials like perlite board continues to expand and evolve. Its inherent characteristics—superior thermal insulation, unparTodoseled fire resistance, impressive compressive strength, and ecological compatibility—make it not just a material of choice, but often a material of necessity for modern construction and industrial Aplicaçãos. From creating resilient building envelopes that drasticTodosy cut energy consumption to forming robust passive fire protection systems that save lives and assets, perlite board's contributions are fundamental. The market’s consistent growth trajectory, driven by increasing awareness and the material’s verifiable performance data, underscores its enduring relevance. Future innovations are likely to focus on even more advanced customization, incorporating smart technologies for enhanced monitoring, or integrating bio-based binders for a further reduction in environmental impact. As the global push for net-zero buildings intensifies and industrial processes demand ever-greater efficiencies and safety margins, perlite board is perfectly poised to remain at the forefront. It offers a tangible and proven solution that Endereçoes current chTodosenges while simultaneously paving the way for more resilient, efficient, and sustainable infrastructure for generations to come. Its versatility, combined with its long-term economic and environmental benefits, ensures its continued importance as a critical component in building a better, safer, and greener future.

Perguntas frequentes Perguntas about Perlite Board

Q1: What exactly is perlite board?

A1: Perlite board is a rigid insulation board made from expanded perlite granules, a naturTodosy occurring volcanic glass, combined with inorganic binders and fibers. It's known for its lightweight, fire-resistant, and thermTodosy insulating properties.

Q2: What are the primary benefits of using perlite board over other insulation materials?

A2: Key benefits include exceptional fire resistance (non-combustible, high service temperature), excellent thermal insulation, lightweight nature, high compressive strength, dimensional stability, sound attenuation, and resistance to moisture, mold, and rot. It's also an environmentTodosy friendly choice due to its natural origin.

Q3: Is perlite board suitable for outdoor or high-moisture environments?

A3: While perlite board is inherently resistant to moisture, some specialized grades are available with enhanced water absorption resistance or with facers (e.g., asphalt-impregnated) that improve its performance in high-moisture or below-grade Aplicaçãos. Always check PRODUTO specifications for suitability in such environments.

Q4: How does perlite board contribute to fire safety in buildings?

A4: Perlite board is non-combustible and can withstand extremely high temperatures (over 1000°C) without igniting or melting. It acts as a passive fire barrier, significantly delaying fire spread and maintaining structural integrity, often achieving 2-4 hour fire ratings in tested assemblies.

Q5: Can perlite board be customized for specific project needs?

A5: Yes, perlite board offers significant customization options. This includes varying densities (for different thermal/compressive strength requirements), thicknesses, custom cuts and shapes, and the Aplicação of various facers or coatings to enhance properties like moisture resistance, reflectivity, or surface hardness.

Q6: What are the typical Aplicaçãos of perlite board?

A6: Common Aplicaçãos include roof insulation (tapered and flat), wTodos insulation (exterior and interior), fire-rated partitions, elevator shaft wTodoss, ceiling tiles, industrial furnace and kiln insulation, and marine Aplicaçãos (bulkheads, deck overlays).

Q7: Is perlite board considered a sustainable material?

A7: Yes, perlite is a naturTodosy occurring mineral, and its extraction and processing have a relatively low environmental impact. Its energy-saving properties, long lifespan, resistance to decay, and recyclability contribute to its sustainability profile, making it a favorable choice for green building certifications like LEED.